Interfacial Accessories

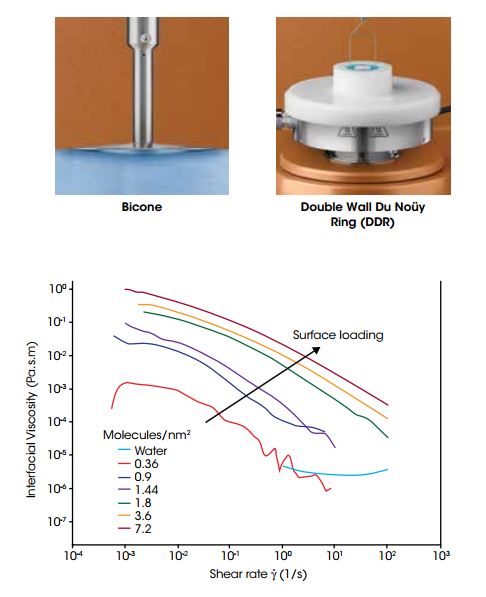

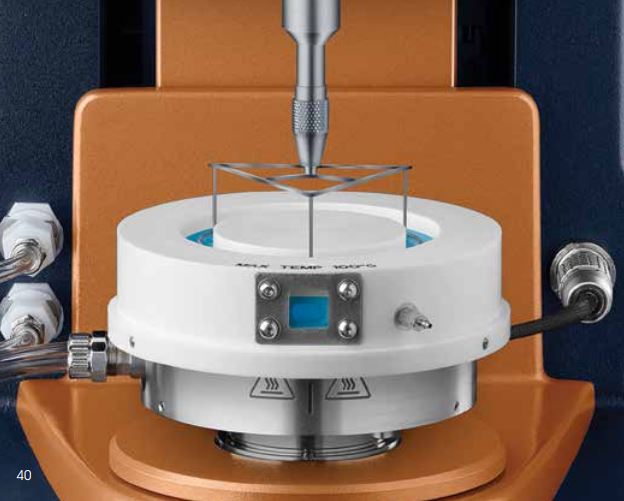

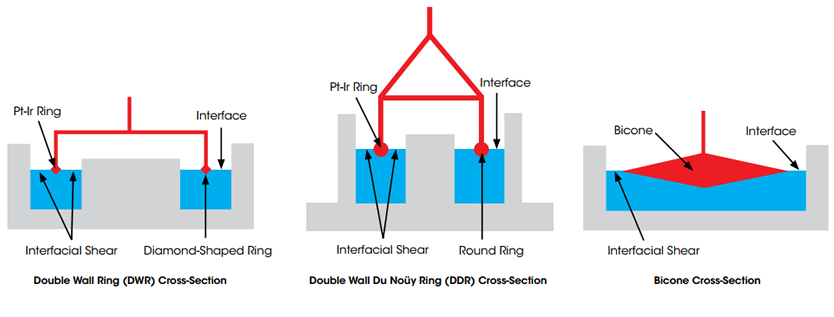

Rheometers are typically used for measuring bulk or three-dimensional properties of materials. In many materials, such as pharmaceuticals, foods, personal care products and coatings, there is a two-dimensional liquid/liquid or gas/liquid interface with distinct rheological properties. Only TA Instruments offers three separate devices for the most flexibility and widest range of quantitative measurements for the study of interfacial rheology. The options include a patented Double Wall Ring (DWR) system for quantitative viscosity and viscoelastic information over the widest measurement ranges, a Double Wall Du Noüy Ring (DDR) for samples available in limited volumes, and a traditional Bicone for interfacial viscosity measurements.

Application

In this series of tests, the surfactant SPAN65 was spread evenly at the water-air interface using a solution of SPAN in chloroform. After the evaporation of the chloroform, the SPAN65 film deposited on the water was measured using the Double Wall Ring Interfacial accessory. Different loadings of surfactant were tested from 0 (just water, no surfactant layer) to 7.2 molecules per nm2. Continuous shear experiments were conducted and the interfacial viscosity was measured as a function of shear rate and interfacial concentration. As expected, the surfactant layer shows significant shear thinning. At high rates, the sub-phase contributions dominate for the loadings less than 1.8 molecules/nm2. Sub-phase correction becomes important below an interfacial viscosity of 10-5 Pa.s.m and the well-defined geometry of the DWR makes these quantitative sub-phase corrections possible. At higher interfacial viscosities, sub-phase contributions are negligible and the correction is unnecessary.

Technology

In all TA Instruments interfacial rheology systems, the sample is contained in a Delrin trough complete with fluid level monitoring windows and injection ports. The measuring rings of the Double Wall Ring (DWR) and Double Wall Du Noüy Ring (DDR) geometries are made of platinum-iridium. These materials are selected for their inert chemistry and ease of cleaning. TA Instruments is the only supplier offering patented double wall geometry configurations that provide interfacial shear planes on both sides of the geometry surface for higher sensitivity to the monolayer viscoelastic response. Only the DWR is capable of truly quantitative viscoelastic parameters because the interface is “pinned” to the diamond-shaped cross-section of the geometry ring. This patented ultra-low inertia ring(1) has a diameter of 60 mm and was designed for ease-of-use and maximum sensitivity. Surface viscosity measurements can be conducted on surface viscosities as low as 10-5 Pa.s.m without complicated sub-phase corrections. And, oscillation measurements are possible over the widest frequency range of any interfacial system. The Du Noüy ring geometry of the DDR is an industry standard device used for surface tension measurements. The round cross-section allows for meniscus formation between the interface and geometry, creating a slight error in the absolute data. With a much smaller diameter of 20 mm, this system is ideal for testing interfacial properties of samples that are available in very limited quantities, such as biological or pharmaceutical materials. The Bicone is a double conical stainless steel geometry with a sharp edge that reproducibly pins the interface. Because of the large drag created by the surface of the cone submerged within the sub-phase, large corrections are required to obtain quantitative parameters. The geometry’s large moment of inertia limits measurement capability to interfacial viscosity in steady shear mode, precluding valuable measurements of quiescent structure and elasticity. (1) U.S. Patent #