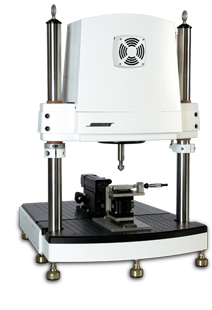

Unmatched dynamic performance envelope and versatility for applications that require up to 3 kN.

View brochure The New 3310 Contact Us

Sales Promotions

Key Features

- High resolution and high accuracy displacement measurement

- Static to 100 Hz dynamic performance for a variety of applications

- Optional 14 Nm, 24 Nm, or 49 Nm torsional motor is available for multi-axial test applications

- Accommodates a variety of environmental chambers including temperature-controlled saline baths and hot/cold chambers

3300 Series Spec Table

| Product Specifications | ElectroForce 3310 | ElectroForce 3330 |

| Force – Peak/Max Sine (N) | ± 1000 N | ± 3000 N |

| Force – Static or RMS (continuous) | ± 700 N | ± 2100 N |

| Displacement | 25 mm | 25 mm |

| Linear Velocity | 0.013 μm/s – 1.5 m/s | 0.013 μm/s – 2.0 m/s |

| Frequency | 0.00001 Hz – 100 Hz | 0.00001 Hz – 100 Hz |

| Torsional Motor Options | ||

| Standard Torque Option | ||

| Torque – Peak/Max | ± 14 N-m | ± 24 N-m |

| Torque – Static or RMS (continuous) | ± 14 N-m | ± 24 N-m |

| High Torque Option | ||

| Torque – Peak/Max | – | ± 49 N-m |

| Torque – Static or RMS (continuous) | – | ± 42 N-m |

| Rotation | Multi-Turn (+/-10 revolutions Standard) | Multi-Turn (+/-20 revolutions Standard) |

| Extended Stroke (ES) Option | ||

| Displacement | 150 mm | 150 mm |

Motor Technology Benefits

Reliable testing

Reliable testing

- 10-year ElectroForce motor warranty

- ElectroForce motor designed, developed and manufactured by TA Electroforce to exacting standards

- Frictionless design ensures optimal control and long-life for a variety of durability testing applications

High-fidelity, responsive control

High-fidelity, responsive control

- Accurate control and high-resolution performance provides more precise material properties

- Very low motor moving-mass provides industry leading frequency response

Low-force control applications

Low-force control applications

- No motor friction or stiction provides accurate, low-force testing

- Excellent control from below 5N loads to 3kN, providing versatility for a variety of tests.

Clean, electromagnetic technology

Clean, electromagnetic technology

- Standard ElectroForce systems can be used in clean rooms or incubators for exceptional versatility

- Efficient electromagnetic power conversion is well-suited for a variety of test environments

Energy-efficient technology

Energy-efficient technology

- Efficient power utilization reduces operating costs

- Lab-friendly instruments and easy installation allows testing to start immediately

- No expensive infrastructure or contamination – saves upfront costs and operating expense

Software Technology Benefits

Easy-to-use, flexible software

Easy-to-use, flexible software

- Test setup and status window to guide users

- Customizable windows and views

- Intuitive and configurable test setup

- Multiple test monitoring sources

Direct control over your data

Direct control over your data

- Customizable and flexible data collection

- Control of data acquisition before and during the test

- Data is stored even if test stops unexpectedly

Real-time test parameter control

Real-time test parameter control

- Adjust waveforms in real-time

- No need to stop test to reconfigure major test parameters

Security and history tracking

Security and history tracking

- User login for added security

- Secure workspace with audit trail traceability

- File system security to protect test files

3300 Series II Axial/Torsion

3300 Series II Axial/Torsion

3300 Series II Axial/Torsion

Combined axial and torsion loading that offers rotation and torque control

3300 Series II Multi-Specimen Fatigue

3300 Series II Multi-Specimen Fatigue

3300 Series II Multi-Specimen Fatigue

The ElectroForce 3300 MSF is ideally suited for characterizing the fatigue life of cardiovascular devices.

Multi-Specimen Fatigue Instrument

3300 Series II Dental Wear

3300 Series II Dental Wear

3300 Series II Dental Wear

The ElectroForce 3300 Dental Wear configuration integrates a horizontal mover to simulate two-body wear that occurs during chewing.