Superior control, in displacement and force, and unparalleled performance for characterizing the anisotropic behavior of materials and soft tissues.

Sales Promotions

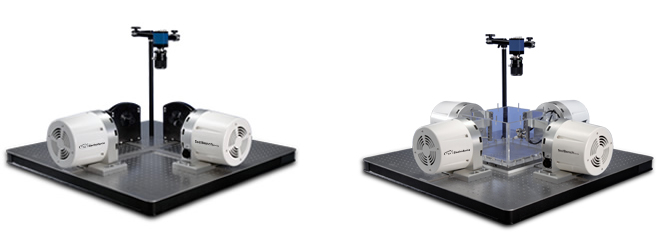

The ElectroForce Planar Biaxial TestBench instrument offers superior control and unparalleled performance in material and soft tissue characterization. Using this instrument, you can assess mechanical anisotropy and stress-strain relationships in samples that range from engineered devices, including wearable sensors and wound repair meshes, to tissues such as skin, pericardium, and heart valve leaflets. This instrument can be configured with either two or four ElectroForce linear motors mounted on a horizontal baseplate and load cell options for each axis of loading

Key Features

- Superior performance: choose parameters for your test protocol without compromising accuracy, including force, displacement, frequency, and wave shape (loading profile)

- Controllability: precisely characterize different materials by controlling specific experimental parameters, including load, displacement, and strain control (with theDigital Video Extensometer (DVE))

- Tailored for specific research needs: upgrade to a 4-motor configuration or add accessories such as hook or clamp tensile grips, heated saline bath, sterile BioDynamic chamber, or extended stroke and torsion actuators

- Integrated non-contact strain measurements: perform 2-D strain measurements in a physiologically-relevant environment with the DVE

Motor Technology Benefits

Reliable testing

Reliable testing

- 10-year ElectroForce motor warranty

- ElectroForce motor designed, developed and manufactured by TA Electroforce to exacting standards

- Frictionless design ensures optimal control and long-life for a variety of durability testing applications

High-fidelity, responsive control

High-fidelity, responsive control

- Accurate control and high-resolution performance provides more precise material properties

- Very low motor moving-mass provides industry leading frequency response

Low-force control applications

Low-force control applications

- No motor friction or stiction provides accurate, low-force testing

- Excellent control from gram-force loads to 200N, providing versatility for a variety of tests

Clean, electromagnetic technology

Clean, electromagnetic technology

- Standard ElectroForce systems can be used in clean rooms or incubators for exceptional versatility

- Efficient electromagnetic power conversion is well-suited for a variety of test environments

Energy-efficient technology

Energy-efficient technology

- Efficient power utilization reduces operating costs

- Lab-friendly instruments and easy installation allows testing to start immediately

- No expensive infrastructure or contamination – saves upfront costs and operating expense

Software Technology Benefits

Easy-to-use, flexible software

Easy-to-use, flexible software

- Test setup and status window to guide users

- Customizable windows and views

- Intuitive and configurable test setup

- Multiple test monitoring sources

Direct control over your data

Direct control over your data

- Customizable and flexible data collection

- Control of data acquisition before and during the test

- Data is stored even if test stops unexpectedly

Real-time test parameter control

Real-time test parameter control

- Adjust waveforms in real-time

- No need to stop test to reconfigure major test parameters

Security and history tracking

Security and history tracking

- User login for added security

- Secure workspace with audit trail traceability

- File system security to protect test files