5 Things You Will See When You Upgrade to a Discovery Hybrid Rheometer HR-3

See Better Low Torque Sensitivity and Stability

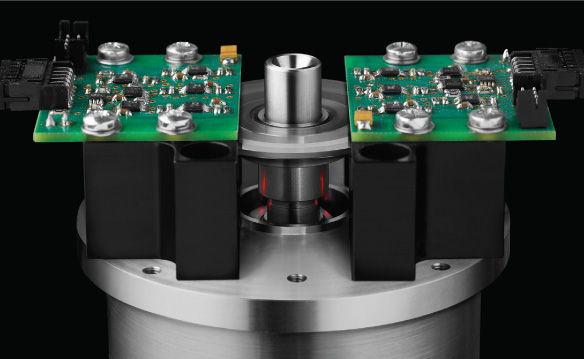

The Discovery Hybrid Rheometer is the only commercial rheometer with a magnetic thrust bearing and our second generation design offers improved low torque performance and stability. The magnetic thrust bearing design eliminates drag from pressurized air flows, resulting in a 70% reduction in bearing friction. This allows the DHR motor to measure 0.5 nN.m of torque. The new magnetic bearing design enables measurement of these lowest torque values while also making the bearing even more robust and easy to use. This allows for the measurement of low viscosity samples and low sample volumes.

See More Accurate Strain and Phase Angle Data

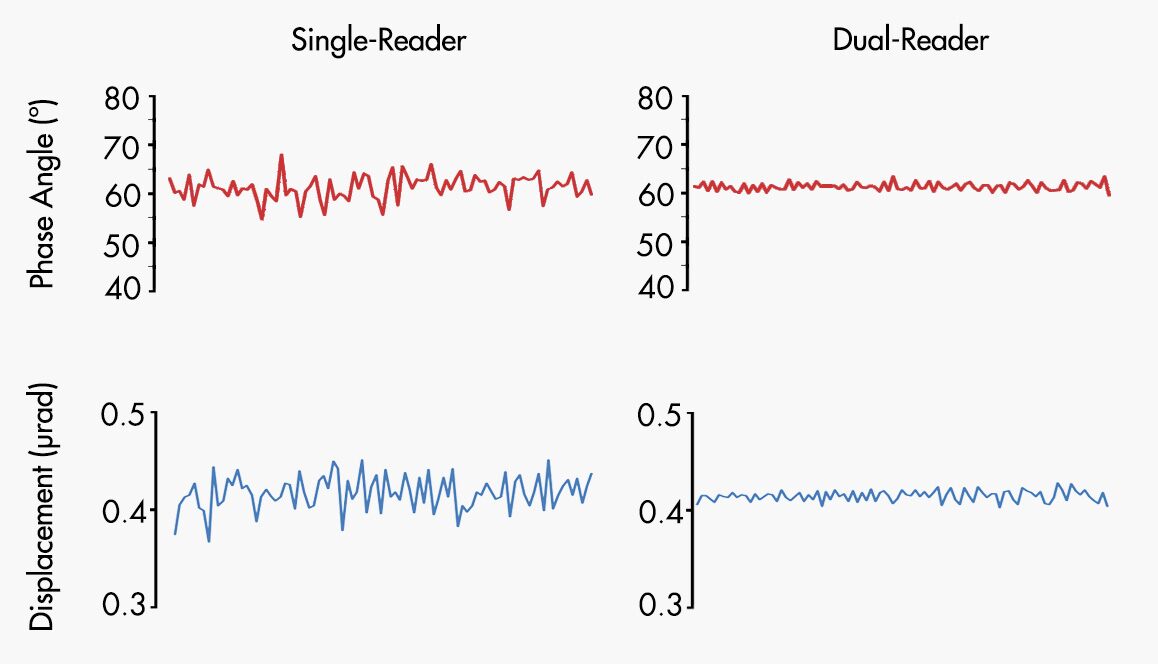

The all new Optical Encoder Dual-Reader greatly improves the measurement of displacement, resulting in visibly improved strain measurement and control, as well as phase angle values. The Dual-Reader reduces measurement noise, allowing for ultra high displacement resolution up to 2 nanoradians. This measurement quality also improves phase angle measurement, allowing low levels of elasticity in a fluid or trace amounts of damping in a solid to be easily and accurately identified.

The single piece aluminum casting and linear ball slide creates a rigid test platform, eliminating torsional compliance and system damping. This ensures that the Discovery Hybrid Rheometer is the most stable platform for the most sensitive measurements of soft, as well as stiff, materials.

Optical Encoder Single-Reader vs. Optical Encoder Dual-Reader

Superior Normal and Axial Force Performance

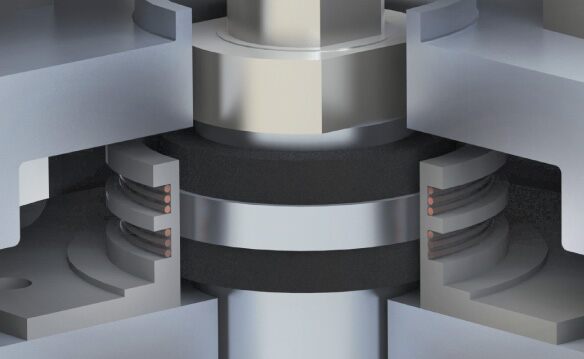

Normal force measurements and axial force control demand the fastest and most sensitive measurements. The new Force Rebalance Transducer (FRT) of the Discovery Hybrid Rheometer is a high-sensitivity force measurement device that actively drives to maintain zero displacement. This eliminates compliance and reduces response time, allowing for the most accurate measurement of normal stress responses in transient step shear experiments. The FRT also improves the quality of axial force control, allowing a constant compressive or tensile forces to be applied to a sample even during very fast dimensional changes.

Stable and Accurate Gap Measurements at All Times

The Discovery Hybrid Rheometer provides the most stable and accurate gap values under all test conditions through a combination of thermal expansion compensation, the rigid Force Rebalance Transducer, and the all new True Position Sensor. This high resolution linear position sensor ensures the most accurate data, by measuring and compensating for the effects of thermal expansion in real time. The True Position Sensor eliminates thermal expansion errors in all Smart Swap geometries and Smart Swap environmental systems. This technology is coupled with the inherent system rigidity provided by the Force Rebalance Transducer and single piece aluminum casting to ensure that gap values are stable and accurate, providing even greater confidence in measured material properties.

Find the Right Tool for the Job, Every Time

This Discovery Hybrid Rheometer features the most extensive line of Smart Swap geometries, environmental systems and accessories, ensuring you have the right rheometer for every job. These systems are easily interchanged and automatically configured by the TRIOS software for optimum performance. Attachment and alignment of Smart Swap accessories is made easy by the unique electronmagnetic mounting system which allows for complex systems to be exchanged in seconds.