Plate Accessory

Delay edge fracture for unprecedented non-linear rheology measurements.

The new ARES-G2 Cone and Partitioned Plate Accessory (CPP) expands testing capabilities for highly elastic materials at large deformations in both oscillation and steady shear. The CPP geometry is a modification of the conventional cone-plate test configuration in which only the central portion of the plate is coupled to the stress measurement. This creates a “guard ring” of sample around the active measurement area, delaying the effects of edge failure, allowing for higher strains to be measured on elastic materials. Uniform and stable temperature control is provided by the Forced Convection Oven (FCO). The CPP is unique to the ARES-G2 and further extends its advantages for LAOS testing and polymer rheology.

Features and Benefits:

- Unique geometry for LAOS testing, polymer rheology

- Stable and responsive temperature control through FCO from -150 °C to 600 °C

- 10 mm upper plate connected to the transducer

- 25 mm annular plate surrounds the 10 mm plate and provides a “guard ring”

- 25 mm, 0.1 rad lower cone

- Easy to install, align, and clean

- Greatly reduces effects of sample trimming

- Removes operator dependence for increased reproducibility

Technology:

The Cone and Partitioned plate geometry consists of a 25 mm annular plate with a hollow shaft that is affixed to the ARES-G2’s frame. A 10 mm plate is centrally located within the annulus and is the active measurement surface attached to the torque/normal force transducers. The lower geometry is a 25 mm 0.1 rad cone. Since the measurement is made at the inner 10 mm plate, the data are unaffected at onset of edge fracture – this allows unprecedented access to Large Amplitude Oscillatory Shear (LAOS) testing and steady shear testing of materials like polymer melts. Further, the sample edge at the measuring surface is exposed to an infinite sea of the same material; therefore, the influence of sample trimming is greatly reduced thereby improving data reproducibility and minimizing operator dependence. Finally, the geometry requires minimal alignment and can be easily removed for cleaning.

The Cone and Partitioned plate geometry consists of a 25 mm annular plate with a hollow shaft that is affixed to the ARES-G2’s frame. A 10 mm plate is centrally located within the annulus and is the active measurement surface attached to the torque/normal force transducers. The lower geometry is a 25 mm 0.1 rad cone. Since the measurement is made at the inner 10 mm plate, the data are unaffected at onset of edge fracture – this allows unprecedented access to Large Amplitude Oscillatory Shear (LAOS) testing and steady shear testing of materials like polymer melts. Further, the sample edge at the measuring surface is exposed to an infinite sea of the same material; therefore, the influence of sample trimming is greatly reduced thereby improving data reproducibility and minimizing operator dependence. Finally, the geometry requires minimal alignment and can be easily removed for cleaning.

LAOS Measurements

LAOS Measurements

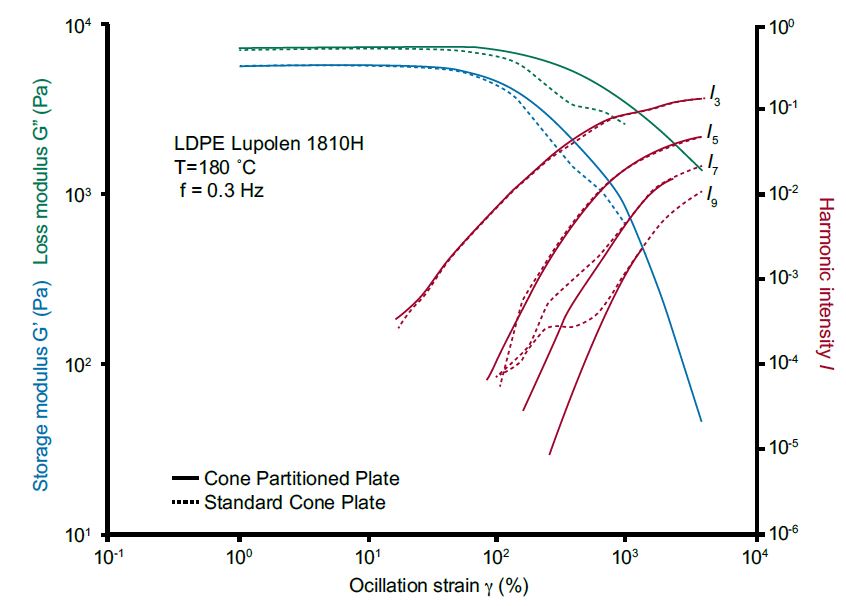

The fundamental shear moduli and the relative harmonic intensities are shown below as a function of strain amplitude for LDPE as measured with a standard cone plate and partitioned cone plate. Up to 80% strain, the results from CPP and standard plates compare favorably. Beyond 80% the reported shear moduli are lower for the standard plates than for the CPP geometry. Edge fracture in the standard cone-plate compromises the sample condition, leading to erroneously low measured modulus values at higher strains. The CPP is less susceptible to this artifact, and reliable data are collected up to 3000% strain. The harmonic intensities agree well, although severe fracturing disqualifies the shear moduli above 80% strain.

Transient viscosity and normal force measurements

Transient viscosity and normal force measurements

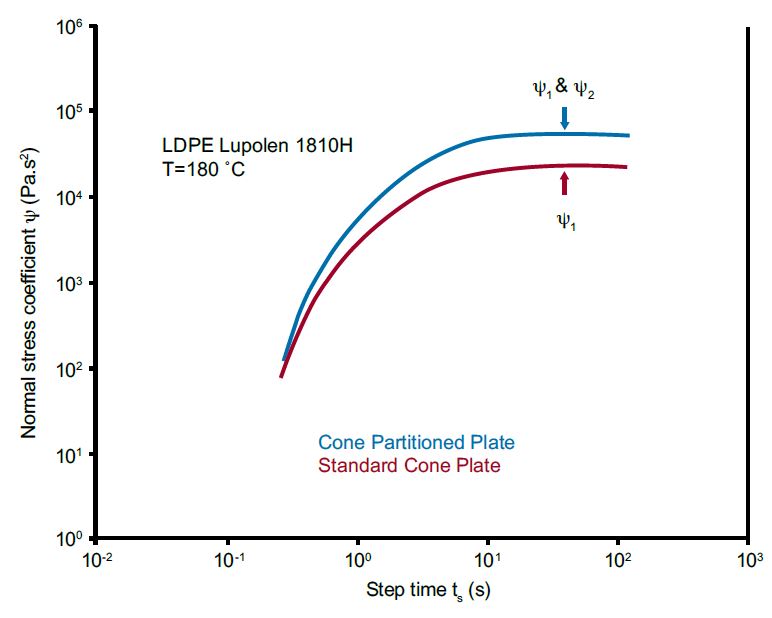

The partitioned plate also provides more consistent steady state results at high strains. With the partitioned plate configuration, the measured normal force is a result of the 1st and 2nd normal stress differences. From experiments with both standard and partitioned cone plate geometries, the 2nd normal stress difference can be extracted.