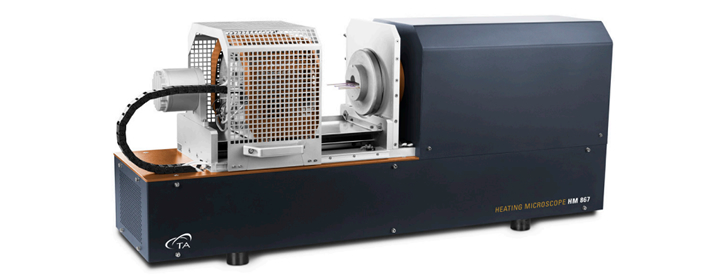

The Heating Microscopes HM 867 are the ideal instruments to study flattening/melting behavior.

Result of over twenty years of R&D of optical instruments for the study of the thermo-mechanical behavior of materials, HM 867 makes possible the analysis of samples beyond the limits of classical heating microscopy. Its versatility makes of HM 867 the most innovative tool for both R&D and for the optimization of all the industrial processes that involve thermal cycles.

Adopting state-of-the-art technologies in the field of optical and thermal analysis, it is supplied with Misura 4 Thermal Analysis software, the proven software platform that provides an intuitive interface for instrument control and data handling and features the most thorough and precise image analysis.

Equipped with a 5Mpix high resolution camera, is used to study the physical behaviour of the materials during the industrial firing cycles. With the evolutionary and innovative software “Morphometrics” it is possible, in real-time during the analysis, to automatically calculate and visualize different characteristic temperatures and parameters selectable by the user.

Capable to analyze samples in a wide range of shapes and sizes (for example a 3mm sample and simultaneously a 10mm sample), HM 867 can also simultaneously analyze up to 8 3x2mm samples.

|

HM 867 |

|

| Optical measuring system | Optical measuring system equipped with a 5 MPix HiRes videocamera |

| Operating modes | Heating microscope |

| International Standards | ASTM D1857, CEN/TR 15404:2010, BS 1016:Part 15:1960, CEN/TS 15370-1:2006, DIN 51730,DM 05-02-1998, IS 12891:1990, ISO 540:1995, NF M03-048 |

| Sample displacement | Bidimensional |

| Sample number | From 1 up to 8, depending upon samples sizes |

| Temperature range on specimen | RT – 1600 °C |

| Temperature resolution | 0,2 °C |

| Heating rate | 0,1 – 80 °C/min |

| Resolution | 5ppm with ISO standard sample |

| Sample dimensions: | ASTM and ISO standards |

| Certified reference materials | Gold wire – Palladium wire |

| Morphometrics | Height, Width, Contact angle, Height/Width Ratio, Perimeter, Area, Roundness, Eccentricity, Center of mass More and freely user-selectable also possible |

| Atmosphere | User selectable, sw controlled automatic gas switching: air, oxidizing, reducing, quasi-inert |

| Light source | LED |

Misura thermal analysis software has been designed and developed by Expert System Solutions for the management of the instruments and data acquired. Misura represents also the name and trademark of the whole range of our instruments.

The user-friendly features and the ease of usage make Misura thermal analysis software a perfect tool for laboratory and R&D.

Since our company was originally born as a software house, our qualified staff can offer continuous updates on operative systems and on software features, also according to customer needs.

The customer who uses our equipment can manage the data of each instrument by using the same database and software. This allows a complete characterization of the analysed materials and a comparison between the different measurements acquired through heating microscopes, optical dilatometers, optical fleximeters and DTA.

Furthermore, we offer an after sales service based on the Internet, which is the perfect way to solve the majority of the problems. It is very useful and quick and only an internet connection is required.

Acquisition

Acquisition

It allows to carry out an automatic test on a sample during the firing cycle, which is characterised by the requested temperature gradient. It is also possible to set several parameters for the real time acquisition (according to the kind of materials) of the images and data during the firing cycles.

Furthermore, it can analyse automatically the coefficient of expansion, the glass transition temperature and the dilatometric softening temperature and the sintering process of the materials. During the acquisition it is possible to check the expansion and contraction of the material by a real time graph.

Archive

Archive

It is possible to manage the stored tests, recall them to control, modify and print the data and/ or images of the tests. The user has the complete management of the database for the compression and discharge of the data and/or acquired images to peripheral units. Furthermore, it allows to open directly and automatically the pertinent graph for each analysis.

Graphs

Graphs

The data obtained from the memorized data are immediately available in graphs. All curves can be viewed or printed singularly or overlapped with other curves relevant to other tests and it is possible to view or print different curves of the same test: expansion, its first derivative, the second derivative, coefficient of thermal expansion vs. temperature or time profile. Furthermore, it automatically calculates Alpha (α), cubical Alpha value and Delta (Δ) L/L0, the Glass Transition temperature (Tg) and the Dilatometric Softening temperature (Ts) of the thermal expansion curve acquired.

Parameters

Parameters

This function allows to store the parameters for the analysis of the materials, such as the firing cycle and the acquisition interval of the data and/ or images.

Classes

Classes

This function allows to define a file of classes, whose tests can be put together to better classify them (i.e. frits, glazes, enamels, steel…, etc). Inside the card of each test there is a class field, which can be used to separate, for example, the tests carried out in the specific research of a product.

Settings

Settings

Different parameters of Misura can be customized according to the user needs. It is possible to:

- Create or choose a Misura database

- Set the language you want to use

- Choose the font and the size of character to use in the program

- Insert the client logo which will be used on every printout heading

- Define the user password for the access to the software.

Related graphs

Thermal expansion and CTE curves of aluminium compared to the same curves of steel

Related graphs

Optimization of the firing cycle of a stoneware body, given a fixed body formulation. The best firing temperature is the temperature at which the given body composition is able to achieve full densification, with no bloating in the minimum time (in this case 1220°C). Firing above this temperature results in a drastic fall of the mechanical properties and arising of deformations, due to bloating caused by bubbles growth inside the body.

Related graphs

Analysis of coal ashes according to ISO 540 norm.

Related graphs

A piece of zirconia implant subjected to its industrial sintering cycle; the sample shows an isotropic shrinkage (densification) but no changes in shape.

Related graphs

Frit for enamel analysed according to ISO 540 norm. The characteristic points of deformation, sphere, hemisphere and flow are automatically detected.

Related graphs

Flattening curves of ceramic frits. Black curve represents a glassy frit, while red curve represents a crystallizing frit for monoporosa application. After the sintering phase, this curve shows a long plateau indicating that a crystallization is taking place inside the material. As the temperature increases, the material does not behave like a glass but melts with the typical behaviour of a crystalline material.

Related graphs

Analysis of a fuel ash sample according to DIN 51730 norm. This test is important in power plants, because the maximum temperature of the combustion chamber must be regulated to be always lower than the softening temperature of the ash.

Related graphs

Thermal expansion of a palladium – silver alloy for dental implants and C.T.E. calculation.

Related graphs

Thermal expansion and CTE curves of a glaze. The glass transition temperature (Tg) is determined with the tangents method, while the softening temperature (Ts) is identified in correspondence of the peak in the curve. The expansion curve obtained with an optical dilatometer has a wide rising section above the glass transition temperature because the sample is not subject to any pressure. The sharp fall beyond Ts demonstrates that the ends of the sample are rounding off, even though the volume of the material continues to increase as a consequence of thermal expansion, but its length reduces as a result of surface tension.

Related graphs

The ceramization curve of a glass ceramic material is characterized by an initial expansion, followed by a first little shrinkage and the plateau of nucleation of a crystalline phase. After a descending segment in which the glass undergoes an apparent contraction caused by the reduction of the viscosity and a resulting softening of the sample, there is a phase of clear swelling. Crystallization phenomena within the vitreous mass makes the material rigid again.

Related graphs

The state of tension between glaze and body depends essentially on two factors: the relation between their thermal expansion curves and their coupling temperature. The bending curve on a fired glazed piece of tile is fundamental to identify the coupling temperature and also reveals the qualitative level of stress between body and glaze. Combining the flexion curve of the glazed tile with the thermal expansion curves of body and glaze allows a complete quantitative study of the residual stresses. In this case the glaze results under compression.

Related graphs

Enlargement of the most interesting zone of the LTCC sintering curve. An initial shrinkage phase, due to the binder burnout, starts at 292°C and ends at 347°C. After it, the material undergoes a process of low thermal expansion, up to 626°C. This temperature identifies the onset of actual sintering.

Related graphs

Thermal expansion and CTE curves of Invar. Invar is a Ni-Fe alloy characterized by an extremely low thermal expansion coefficient from room temperature up to 200°C.

Related graphs

Multi-layer ceramic chip capacitors are the most widely used passive components in electronics. The shrinkage control is very important; the sintering curve of each layer must match in order to avoid delaminating problems.

Related graphs

The fusibility of continuous casting powders strongly depends on the thermal cycle applied: here is shown the effect of the heating rate on the melting behaviour.

Related graphs

Fusibility test on a 99.99% gold wire.

Related graphs

Comparison between raw materials. Each type of clay shows its own characteristic behaviour of thermal expansion, sintering and swelling.

Related graphs

Sinter-crystallization process of a piece of iron rich glass-ceramic containing slags of steel industry. The sample was pre-treated at 800°C in order to enhance crystal formation, then subjected to 2h dwell at 1080°C. The sintering curve makes clear the densification kinetic and measures a -0.57% contraction at the end of the 2h.

Related graphs

Sintering study of a single anode layer consisting of Ni-YSZ CerMet (125 microns thick) and on a YSZ electrolyte layer (10 microns thick).

Related graphs

Analysis of a RDF ashes sample and study of the influence of the heating rate applied (flash heating, 8°C/min, 80°C/min).

Related graphs

Analysis of a waste ash sample according to ASTM 1857 norm.

Related graphs

Sintering curves of different mixtures ceramic body (porcelain like)-austenitic stainless steel 316L in oxidizing atmosphere.

Related graphs

Fusion test on a welding allow. Determination of the melting point and measurement of the contact angle on stainless steel sample holder.

Optical Contact-less Measurement

Optical Contact-less Measurement

The sample is allowed to freely expand/shrink without any interference due to mechanical contact. This results in a more precise determination of specimen’s behaviour when heated/cooled, as well as of the temperature at which the events are detected. Also, the lack of any load on the sample due to the contact with a measuring system enables to extend the analysis well beyond softening point into the melt, and also analyze soft samples that would otherwise be impossible to test.he HiRes CCD videocamera frames the sample up to 14 times a second, enabling an extremely refined image analysis software to automatically determine the characteristic shapes and temperatures necessary to optimize processing parameters for the production of ceramics as well as the processing of metals or the combustion parameters in power plants.

Morphometrix software

Morphometrix software

The evolution of Misura 3 Image Analysis application, Morphometrics can capture up to 14 frames per second making it possible to automatically determine and visualize, in real-time during the analysis, sample’s characteristic shape’s temperatures. The recognition of shapes can be performed accordingly to a wide range of international standards or also by user-defined parameters and concepts.

All the results, the complete series of original frames and the sample shapes are stored in a database together with analytical parameters in a non-proprietary format file.

Thermostatted Optical Bench Housing

Thermostatted Optical Bench Housing

To ensure the ultimate reproducibility and prevent any short-to-mid term drift, regardless of possible temperature fluctuations due to changed environmental conditions, the housing of the optical bench is actively thermostatted with temperature control in three points. The resulting temperature stability within the housing is +- 1°C.

As a further measure, the support of the optical bench is made of thermally stable materials.

High-performance LED source

High-performance LED source

The LED illumination system operates in the blue range. This significatively improves the resolution as it lowers the limit posed by scattering. As a result it is possible to appreciate smaller changes in shape hence determine with a higher level of accuracy the temperatures of characteristic shapes

Fully Motorized Kiln Operation

Fully Motorized Kiln Operation

For completely automated, error-free operations ODP 868’s furnace rests on a motorized stage ensuring the maximum safety for the user

Flash Mode

Flash Mode

Designed to reproduce the industrial processing conditions, it allows to increase the furnace temperature to a set temperature and then to automatically introduce the specimen in the kiln.

So to heat the sample in a few seconds with heating rates of up to 200°C/sec like in standard manufacturing processes

100 ° C / min Temperature Heating Rates

100 ° C / min Temperature Heating Rates

Up to the temperature range, ODP 868 allows to program heating rates of up to 100°C, enabling users to study the behavior of materials in conditions virtually identical to those used in today’s most demanding manufacturing processes