Mooney Viscometer

Mooney Viscometer incorporates the latest measurement technology for the traditional Mooney viscosity, Mooney scorch, and stress relaxation measurement in the rubber industry.

View brochure Accessories Contact Us

Sales PromotionsThe MV one Mooney Viscometer incorporates the latest measurement technology for the traditional Mooney viscosity, Mooney scorch, and stress relaxation measurement in the rubber industry. The MV one is a fully featured instrument configured for standard viscosity, scorch and stress relaxation (linear, logarithmic, ISO, Mooney Stress-relaxation Rate) testing of rubber compounds under isothermal test conditions at constant speed of 2 rpm. An optional continuously variable motor mode allows tests over a speed range of 0.1 to 10 rpm. The MV one Mooney Viscometer is equipped with low mass rotors that meet all relevant ASTM, ISO, and DIN standards. All TA Instruments rubber testing instruments are constructed on ultra-rigid test frames and include direct drive motors, precision temperature control and the powerful and intuitive Scarabaeus Control and Analysis Software.

Features

- Superior design for unmatched data precision and accuracy

- Extremely rigid test frame for accurate compliance-free data

- Low mass rotor design and direct heating for fast and accurate temperature control

- Available high resolution variable speed direct drive motor

- Automated internal torque calibration

- Long-life user-replaceable seals

- Powerful and Intuitive Scarabaeus Software available in multiple languages

Large (38.10 mm) and small (30.48 mm) diameter rotors Mooney viscosity, stress relaxation, scorch

| Rotational Speed | 2 rpm (Standard)

0.1 to 10 rpm (Optional) |

| Temperature Range | Ambient to 200°C |

| Torque Range | 0.01 to 200 MU |

| Rotors | Large: 38.10 mm D

Small: 30.48 mm D |

| Test Modes | Mooney Viscosity Mooney Scorch Stress Relaxation (Linear, Logarithmic, ISO, Mooney Stress-relaxation Rate) |

| Standards | ASTM D1646, ISO 289, DIN 53525 |

TA Instruments is the world’s leading supplier of analytical instrumentation for the measurement of viscosity and viscoelastic properties. The new rubber testing instruments are uniquely designed to deliver the highest quality of torque, amplitude, frequency, temperature, and pressure measurement and control setting the NEW STANDARD for testing of rubber products at all stages of manufacturing.

Mooney Viscometer Rotors

Mooney Viscometer Rotors

The MV one Mooney Viscometer is compatible with rotors of both large (38.1 mm) and small (30.48 mm) diameters. Both rotors are endorsed by international standards and can be selected for measurement of low or high viscosity rubbers or polymers. Both rotor types can be used in conjunction with polyester or polyamide films to simplify instrument cleaning and reduce time between runs. Rotors are designed with low mass to optimize thermal response and transient speed changes at the beginning and end of shearing steps.

Torque Calibration

Torque Calibration

Calibration is software driven and does not require the use of external weights, fixtures, or reference materials. A weight of known mass is connected by a well-defined radius, creating a constant torque value. The software driven torque calibration routine uses this internal standard to ensure utmost data accuracy.

Mooney Viscometer Experiments

Descriptions and examples of basic and advanced Mooney Viscometer experiments. Mooney Viscometer experiments are easy to perform, provide continuous comparison with historical data, and reveal information about rubber viscosity and elasticity. Mooney Viscometer experiments are easy to perform, provide continuous comparison with historical data, and reveal information about rubber viscosity and elasticity. Typical tests include Mooney Viscosity, Stress Relaxation, and Scorch. More advanced experiments at multiple rates provide additional insight into polymer shear rate dependence.

Mooney Viscosity

Mooney Viscosity

The Mooney Viscosity test is a well-established method for characterizing uncured rubber materials. Following well- defined standard procedures, the sample is preheated for a defined period, then sheared at a constant rate.The Mooney Viscosity is recorded from the end of this deformation stage. in the present example, the outstanding precision of the MVone Mooney Viscometer is demonstrated. Three polymer samples were tested in duplicate.The outstanding run-to-run reproducibility and the ease of distinguishing one polymer from another is clear.

Suitable Instrument: MV one

Mooney Stress Relaxation

Mooney Stress Relaxation

While the Mooney Viscosity experiment is typically indicative of polymer viscosity, stress relaxation can be used to identify elasticity. Upon completion of the Mooney Viscosity measurement, the rotor is stopped immediately and the torque decay is observed.The slope of this decay is indicative of polymer elasticity, which may be related to a branched architecture and correlates well with extrudate swell in rubber processing.

Suitable Instrument: MV one

Mooney Scorch

Mooney Scorch

The Mooney Viscometer can also be used to measure the initial rate of vulcanization. In this example, a styrene butadiene rubber (SBR) was tested for prevulcanization characteristics at 150°C using the small rotor. For this simple experiment the initial Mooney viscosity, minimum viscosity, scorch times, and cure index are the most commonly reported values.

Suitable Instrument: MV one

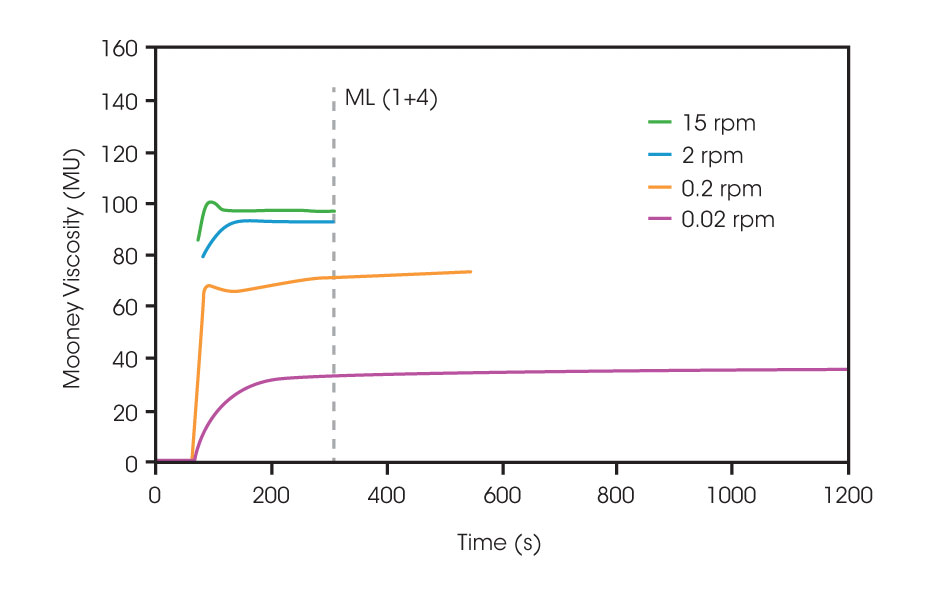

Mooney Viscosity at Multiple Rates

Mooney Viscosity at Multiple Rates

In addition to the viscosity at a single rate and temperature, the MV one Mooney Viscometer can measure viscosity at a range of shear rates and temperatures. This range of rates allows a more complete understanding of the polymer behavior, especially a tendency for shear thinning. Low rates in Mooney Viscosity experiments can also be beneficial for measuring highly elastic materials that are otherwise inaccessible to Mooney Viscosity measurements.

Suitable Instrument: MV one