Utilizes state-of-the-art, non-contact, linear drive technology to provide precise control of stress, and air bearings for low friction support.

Sales Promotions| Maximum Force | 18 N |

| Minimum Force | 0.0001 N |

| Force Resolution | 0.00001 N |

| Strain Resolution | 1 nanometer |

| Modulus Range | 103 to 3×1012 PA |

| Modulus Precision | ±1% |

| TanA Sensitivity | 0.0001 |

| TanA Resolution | 0.00001 |

| Frequency Range | 0.01 to 200 Hz |

| Dynamic Sample Deformation Range | ±0.5 to 10,000 pm |

| Temperature Range | -150 to 600 °C |

| Heating Rate | 0.1 to 20 ‘C/min |

| Cooling Rate | 0.1 to 10 °C/min |

| Isothermal Stability | ±0.1 °C |

| Time/Temperature Superposition | Yes |

![]() mouse over the

mouse over the ![]() icons for details.

icons for details.

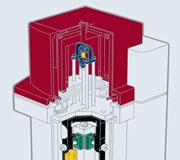

![]() Drive Motor

Drive Motor

Magnetic drive motor for precise stress control over a wide force range

![]() Air Bearing

Air Bearing

Unique low-friction air bearing design and enhanced sensitivity for measuring weak samples

![]() Furnace

Furnace

Automatic movement for opening and closing furnace and precise temperature control over the entire temperature range

Cantilever

Cantilever

Cantilever

Ideal for general purpose mode for evaluating thermoplastics and highly damped materials, the sample is clamped at both ends.

3 Point Bend

3 Point Bend

3 Point Bend

The sample is supported at both ends and force applied to the middle, considered the purest mode of deformation. Ideal for high modulus materials.

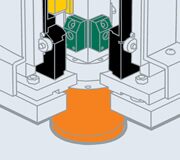

Shear Sandwich

Shear Sandwich

Shear Sandwich

Ideal for gels, adhesives and high viscosity materials. This clamp uses two sample pieces sheared between a fixed movable plate.

Compression

Compression

Compression

Used for low modulus materials, the sample is placed on a fixed flat surface with an oscillating plate applying force.

Tension

Tension

Ideal for films, fibers and low modulus materials. A spring loaded grip insures constant contact with the sample.

Submersible

Submersible

Submersible

Available for both film and compression clamps the submersible clamps are ideal for testing bio materials.

Isostrain

Strain is help constant during a temperature ramp.

Multi-Frequency

The Multi-Frequency mode can access viscoelastic properties as a function of frequency. Test can be run at single or multiple frequencies.

Creep Stress/Relaxation Mode

With creep the stress is held constant and deformation is monitored as a function of time. In stress relaxation, the strain is held constant and the stress is monitored vs time.

Multi Stress/Strain Mode

In this mode frequency and temperature are held constant and the viscoelastic properties are monitored and stress and strain varied.

Controlled Force/Strain Rate Mode

The temperature is held constant while stress or strain is ramped at a constant rate. Also in this mode stress can be held constant with a temperature ramp while strain is monitored.

Air Chiller System 3

Air Chiller System 3

The new Air Chiller System, ACS-3 is a unique gas flow cooling system. It is equipped with a three-stage cascading compressor design, enabling testing to unprecedented temperatures as low as -100°C. This flexible Air Chiller is available for use with the DMA Q800, all DHR Rheometer models with ETC, and the ARES-G2 Rheometer & RSA-G2 Solids Analyzer with FCO. The ACS-3 can help eliminate or reduce liquid nitrogen usage and associated hazards from any laboratory and offers an incredible return on investment estimated between two to three years.

The new Air Chiller System, ACS-3 is a unique gas flow cooling system. It is equipped with a three-stage cascading compressor design, enabling testing to unprecedented temperatures as low as -100°C. This flexible Air Chiller is available for use with the DMA Q800, all DHR Rheometer models with ETC, and the ARES-G2 Rheometer & RSA-G2 Solids Analyzer with FCO. The ACS-3 can help eliminate or reduce liquid nitrogen usage and associated hazards from any laboratory and offers an incredible return on investment estimated between two to three years.

Air Chiller System 2

Air Chiller System 2

The new ACS-2 is a unique two-stage air chiller system for subambient temperature control and general cooling for rheology and DMA systems, but with a higher minimum temperature than the ACS-3 (-55 °C). Supported instruments and environmental systems include the DMA Q800 with standard furnace, Discovery Hybrid Rheometer models with Environmental Test Chamber and ARES-G2/ RSA-G2 with Forced Convection Oven. The ACS-2 can help eliminate or reduce liquid nitrogen usage and associated hazards from any laboratory and offers an incredible return on investment estimated between two to three years.

The new ACS-2 is a unique two-stage air chiller system for subambient temperature control and general cooling for rheology and DMA systems, but with a higher minimum temperature than the ACS-3 (-55 °C). Supported instruments and environmental systems include the DMA Q800 with standard furnace, Discovery Hybrid Rheometer models with Environmental Test Chamber and ARES-G2/ RSA-G2 with Forced Convection Oven. The ACS-2 can help eliminate or reduce liquid nitrogen usage and associated hazards from any laboratory and offers an incredible return on investment estimated between two to three years.

Gas Cooling Accessory

Gas Cooling Accessory

The Gas Cooling Accessory (GCA) extends the operating range of the Q800 DMA to subambient temperatures. The GCA uses cold nitrogen gas generated from controlled heating of liquid nitrogen. Automated filling of the GCA tank can be programmed to occur either after the scan is complete or during a run. This ability to automatically refill during the middle of a run is particularly useful during long DMA experiments typically encountered when generating data for Time/Temperature Superposition (TTS).

Nitrogen Purge Cooler

Nitrogen Purge Cooler

The Nitrogen Purge Cooler (NPC) is an innovative alternative for low temperature testing with the Q800 DMA. The NPC provides crash-cooling and controlled heating at temperatures as low as -160°C with all testing geometries. It is also an ideal choice for minimizing the cool-down time between consecutive experiments. A 2.5 L liquid-nitrogen filled dewar with heat exchanger cools nitrogen gas (2 bar to 8 bar, 30 LPM) before being fed to the Q800 oven. The NPC is a small, economical, and effective option for laboratories that have basic cooling requirements.

The Nitrogen Purge Cooler (NPC) is an innovative alternative for low temperature testing with the Q800 DMA. The NPC provides crash-cooling and controlled heating at temperatures as low as -160°C with all testing geometries. It is also an ideal choice for minimizing the cool-down time between consecutive experiments. A 2.5 L liquid-nitrogen filled dewar with heat exchanger cools nitrogen gas (2 bar to 8 bar, 30 LPM) before being fed to the Q800 oven. The NPC is a small, economical, and effective option for laboratories that have basic cooling requirements.

DMA-RH

DMA-RH

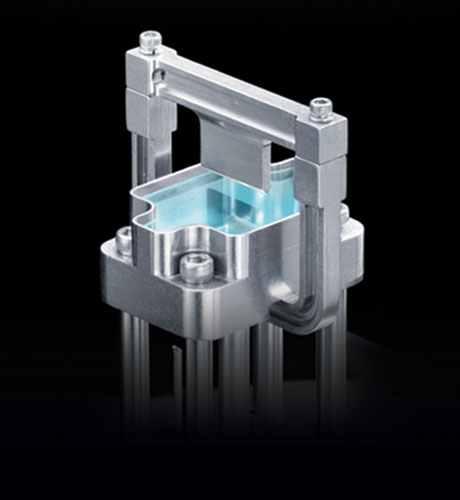

Q800 Clamp Kits

Q800 Clamp Kits

The Q800 offers all the major deformation modes required to characterize solid bars, elastomers, soft foams, thin films and fibers. The deformation modes include bending (single/dual cantilever and 3-point bend), shear, compression, and tension.

- Single/dual cantilever bending

- 3-point bend

- Shear

- Compression

- Film tension

- Fiber tension

In addition, submersible compression and tension clamps are available.

Q800 Submersible Clamp Kits

Q800 Submersible Clamp Kits

Some DMA applications require that the sample be run immersed in a liquid. Both the film tension and compression clamps are available in submersible versions. The clamps are easy to use and provide the ability to run in liquids up to 80°C. The kits include all the necessary tools and calibration samples.

Some DMA applications require that the sample be run immersed in a liquid. Both the film tension and compression clamps are available in submersible versions. The clamps are easy to use and provide the ability to run in liquids up to 80°C. The kits include all the necessary tools and calibration samples.

Air Compressor Accessory

Air Compressor Accessory

The Q800 uses air bearings for support of the drive shaft. The air bearings use a clean, dry compressed air or nitrogen supply that typically comes from a centralized supply. In cases where this is not possible, the Air Compressor Accessory (ACA) is available. This self-contained air compressor provides the clean, dry air supply required for the air bearings.

5 Year Warranty on Cells and Furnaces

5 Year Warranty on Cells and Furnaces We surveyed 2500 customers and here’s what they said about TA…

We surveyed 2500 customers and here’s what they said about TA… Q800 Dynamic Mechanical Aanalysis Brochure

Q800 Dynamic Mechanical Aanalysis Brochure Find Out What Our Customers Are Saying About TA

Find Out What Our Customers Are Saying About TA Dynamic Mechanical Analysis of Polymers

Dynamic Mechanical Analysis of Polymers Improvements in DMA Measurements Using Low-Friction 3-Point Bending Clamps

Improvements in DMA Measurements Using Low-Friction 3-Point Bending Clamps Characterization of printed circuit board materials by DMA

Characterization of printed circuit board materials by DMA Characterization of packaging films performance by DMA creep recovery

Characterization of packaging films performance by DMA creep recovery Measurement of the glass transition temperature using Dynamic Mechanical Analysis

Measurement of the glass transition temperature using Dynamic Mechanical Analysis DMA-RH Accessory

DMA-RH Accessory Polypropylene Impact Resistance by Dynamic Mechanical Analysis

Polypropylene Impact Resistance by Dynamic Mechanical Analysis