Thermal Analysis for Printed Circuit Boards (PCBs)

Morgan Ulrich | Gray Slough

January 22, 2024

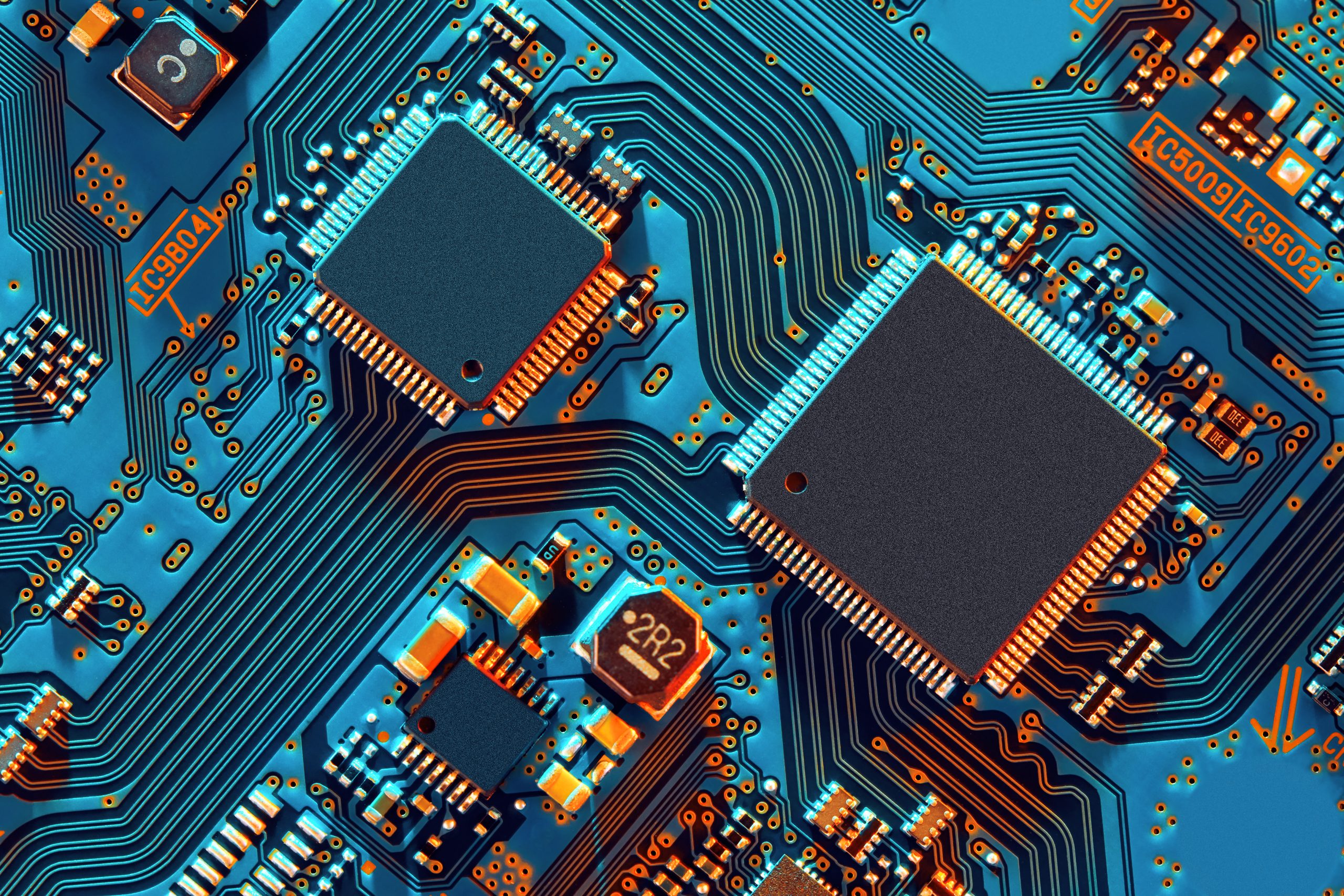

Printed circuit boards (PCBs) form the backbone of virtually all electronic applications. Enhancing their performance and reliability is paramount for custom PCB projects, where smaller footprints and improved maintainability lead to enhanced functionality. However, ensuring longevity and consistent performance across diverse conditions requires detailed analysis.

Thermal analysis is an important tool in PCB development, enabling us to understand material behavior at varying temperatures and ensure material stability. Specifically within the context of PCBs, thermal analysis proves invaluable for evaluating the curing properties of coatings and adhesives, materials that are crucial for safeguarding against moisture ingress that can lead to corrosion and circuit board degradation.

Furthermore, thermal analysis offers a quantitative approach to compare the performance of various coatings and assess the degree of cure in PCB materials, enhancing manufacturing efficiency. It also facilitates comparisons of laminate and adhesive performance across different temperature ranges, mitigating the risk of product failure due to heat and stress. Finally, thermal analysis supports recycling end-of-life products, for example through the study of composite materials made from PCB waste.1

Here, we will explore five key thermal analysis techniques specifically tailored for PCB evaluation, shedding light on their central roles in enhancing product performance and reliability.

Five Techniques Used in Printed Circuit Boards (PCBs) Research

Whether you work in early product development assessing laminates or degree of cure, or if you specialize in late product stages to assess final product stability, these five thermal analysis techniques and instruments can simplify your workflow. Outlined below are five key techniques for the thermal analysis of PCBs:

Thermomechanical Analysis (TMA)

Thermomechanical Analysis (TMA) is ideally suited for observing material behavior around the glass transition temperature. In research, TA’s TMA has been employed to track changes in the glass transition of PCB resins and relate those changes to surface finishes and thermal shock.2

In one particular study, a TA Instruments TMA was used to analyze how chemical modifications to a non-conductive adhesive resin impacted its thermal properties with regards to filler dispersion.3 This process involved analyzing the material’s heat expansion properties and subsequently using that data to calculate the coefficients of thermal expansion and track changes in the glass transition. This assessment helped to determine the suitability of the material in question for specific temperature ranges and whether it was likely to cause undesired stress in a PCB due to excessive expansion.

Thermogravimetric Analysis (TGA)

Thermogravimetric analysis (TGA) measures the mass of a sample over time as the temperature changes. One key application of TGA is for assessing the thermal stability of materials. In one study, a research team employed their TA TGA to examine the thermal stability of intrinsically black polyimide films. Polyimide films are renowned for their exceptional environmental stability, and find use in flexible printed circuit boards. The team’s objective was to verify that their process of producing intrinsically black polyimide films did not negatively impact the typical high thermal stability seen in standard polyimide films.4 This investigation exemplifies TGA’s efficacy in assessing the thermal characteristics of materials, a crucial factor in PCB development.

Differential Scanning Calorimetry (DSC)

Differential scanning calorimetry (DSC) is an ideal technique for measuring curing behavior, whether the cure process involves heating or exposure to light. DSC measures the heat required to increase the sample’s temperature and serves as an effective method for characterizing properties such as latent heat of transisions, material transition temperatures, and heat capacity.

Dynamic Mechanical Analysis (DMA)

Dynamic mechanical analysis (DMA) analyzes how a material response changes as a function of applied forces and temperature. One application is to observe how the material changes in response to loading and PCB preparation. This analysis can also be combined with increasing temperatures to better understand how a PCB responds to processes such as soldering.5

Flash Diffusivity

Flash diffusivity is a method often used to measure thermal diffusivity and thermal conductivity and is known for its significant experimental convenience. In this technique, an intense flash of light, usually generated by a laser or xenon source, is used to deliver pulsed heat. Subsequently, the diffusion of this heat energy through the material is quantified using a detector, typically an infrared sensor. Material thermal conductivity can be calculated from this data.

Flash diffusivity allows for precise measurements of heat transport and the characterization of PCBs. It was employed by one set of researchers to study the thermal properties of a nickel-titanium alloy used as a phase change material for improving the thermal management of high-power electronics.6

TA Instruments’ Thermal Analysis Solutions

Thermal analysis methods can assist in all stages of PCB development, from the prototype phase to the final product. All of the above-mentioned studies utlizied TA Instruments’ industry-leading thermal analysis equipment.

Industry professionals often place their trust in TA Instruments’ equipment due to its exceptional reliability, measurement accuracy, and user-friendly and efficient operation. Contact TA Instruments’ electronics experts to find out how our range of state-of-the-art electronics thermal analysis solutions can expedite your product development and help you provide better-quality products to your customers.

References and Further Reading:

- Tian, S., Luo, Y., Chen, J., He, H., Chen, Y., & Zhang, L. (2019). A Comprehensive Study on The Accelerated Weathering Properties of Polypropylene—Wood Composites with Non-Metallic Materials of Waste-Printed Circuit Board Powders. Materials, 12(6), 876. https://doi.org/10.3390/ma12060876

- Froš, D., Dušek, K., & Vesel, P. (2021). Investigation of Impacts on Printed Circuit Board Laminated Composites Caused by Surface Finish Application. Polymers, 13, 3203. https://doi.org/10.3390/polym13193203

- Lee, T. Y., Su, M., Yong, K., Ko, H., Ho, Y., & Sehoon, K. (2020). Epoxy/silane pre-synthesis improving thermal properties and adhesion strength of silica ‑ filled non ‑ conductive adhesive for fine-pitch thermocompression bonding. Journal of Materials Science: Materials in Electronics, 31(2), 1227–1235. https://doi.org/10.1007/s10854-019-02634-w

- Ren, X., Zhang, Y., Liu, Y., Yang, C., Dai, S., Wang, X., & Liu, J. (2022). Preparation and Properties of Intrinsically Black Polyimide Films with CIE Lab Color Parameters Close to Zero and High Thermal Stability for Potential Applications in Flexible Printed Circuit Boards. Polymers, 14, 3881. https://doi.org/10.3390/polym14183881

- TA Instruments. Characterization of printed circuit board materials by DMA. https://www.tainstruments.com/pdf/literature/TA392.pdf

- Sharar, D. J., Wilson, A., & Tsang, H. (n.d.). Intra- and inter-device passive thermal management using solid-solid Nickel Titanium phase change materials. 2022 21st IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), 1–7. https://doi.org/10.1109/iTherm54085.2022.9899587

- Carey, T., Arbab, A., Anzi, L., Bristow, H., Hui, F., Bohm, S., Wyatt-moon, G., Flewitt, A., Wadsworth, A., Gasparini, N., Kim, J. M., Lanza, M., Mcculloch, I., Sordan, R., & Torrisi, F. (2021). Inkjet Printed Circuits with 2D Semiconductor Inks for High-Performance Electronics. Advanced Electronic Materials, 7, 2100112. https://doi.org/10.1002/aelm.202100112

Other Resources

- Webinar – Improving Li-ion Battery Technology through Advanced Material Analysis

- Webinar – Unlock a New Dimension in your Battery Research Through Isothermal Microcalorimetry

- Webinar – Applications for Isothermal Heat Flow Calorimetry – Lithium Ion Battery Chemistry

- Webinar – Enhanced Understanding of Lithium ion Battery Chemistry Through Isothermal Calorimetry

- Application Note – Investigations into Dry Cell Battery Discharge Rates Using TAM Air

- Application Note – The Impact of Electrolyte Additives in Lithium-ion Batteries Determined Using Isothermal Microcalorimetry

- Application Note – Microcalorimetry for studying the electrolyte stability of lithium/manganese dioxide batteries