Rubber Process Analyzer

The latest technology with the most accurate and reproducible data available.

View brochure Sample Cutter Contact Us

Sales PromotionsThe TA Instruments RPA elite rubber process analyzer (RPA) is the most advanced rotorless rotational shear rheometer dedicated to the complete characterization of polymers, rubber and rubber compounds at all stages of manufacture. The RPA elite provides invaluable viscoelastic data on materials that are uncured, through the curing process, and in situ cured materials. The ultra-rigid test frame, high-resolution variable direct drive motor, ultra-stiff wide-range torque transducer, and precision temperature control provide the most precise and accurate torque, viscosity and viscoelastic properties of elastomers over the widest ranges of testing conditions. The fully flexible architecture of the RPA elite enables advanced testing capabilities beyond any other rubber rheometer including: complete post cure viscoelastic characterization, fully programmable sealing pressure, large amplitude oscillatory shear (LAOS) and arbitrary waveform deformations.

Features

- The most advanced design for testing flexibility and unmatched data precision and accuracy

- High resolution variable direct drive motor for absolute strain control

- Proprietary high stiffness, wide torque range transducer with high sensitivity for noise free data

- Extremely rigid test frame for accurate compliance-free data

- Fully programmable testing parameters and methods including: strain, frequency, temperature, time, and sealing pressure

- Widest range and combination of tests and testing conditions available

- Pneumatic locking cylinders with adjustable platen closing force and pressure sensor

- Available autosampler for unattended operation

- User calibration and user replaceable seals

| Frequency | 0.001 To 50 Hz (0.06 To 3,000 cpm) |

| Amplitude | ±0.005 to ±360° arc (continuous) |

| Strain | ±0.07 % to ±5000 % |

| Torque | 0.0001 to 25 N.m |

| Temperature | Ambient to 230 °C |

| Maximum Ramp Rate | 80 °C/min (1.33 °C/s) |

| Die Type | Sealed bicone, 0.48 mm gap |

| Sample Volume | 4.5 cm3 |

| Platen Sealing Pressure | 2 to 8 bar Adjustable |

| Sample Pressure | Optional: 0 to 8,500 kPa |

| Test Modes | Cure (isothermal, ramp, step) Strain (sweep, offset, LAOS) Frequency Sweep Stress Relaxation Advanced (multi-frequency, abitrary waveforms) |

| Measured Data | Torque, Temperature, Frequency, Amplitude, Sample Pressure (optional) |

| Calculated Data | Viscoelastic properties including: G’, G”, G*, S’, S”, S*, tan δ, η’, η”, η*, LAOS Lissajous curves, non-linearities in stress and strain, and more than 550 process parameters including: ts1, TC10, TC50, TC90, S’min, S’max, scorch time, cure rate |

| Standards | ASTM D5289, D6048, D6204, D6601, D7050, D8059; ISO 6502, 13145; DIN 53529 |

TA Instruments is the world’s leading supplier of analytical instrumentation for the measurement of viscosity and viscoelastic properties. The new rubber testing instruments are uniquely designed to deliver the highest quality of torque, amplitude, frequency, temperature, and pressure measurement and control setting the NEW STANDARD for testing of rubber products at all stages of manufacturing.

Rigid Testing Platform

Rigid Testing Platform

Rigid Testing Platform

The RPA elite is built with an ultra-stiff testing frame and crosshead which eliminate the effects of instrument compliance on test data. Instrument compliance, or instrument deformation, produces erroneously low values of measured properties such as modulus and torque, irregular strain and torque waveform signals, and other errors.

Large diameter steel rods and a thick crosshead brace in the H-shaped load frame of the RPA elite provide unmatched rigidity to resist instrument deflection while the motor deforms the sample. This special design ensures that the commanded strain is achieved with each cycle of deformation, even for highly filled, fully cured rubbers. Additionally, a non-compliant system allows for truly sinusoidal strain profiles under all conditions. This can be verified by continuous Fourier Transform analysis of the deformation and measured torque signals which is available in the Scarabaeus Software. The superior design also guarantees smooth travel, proper alignment, and precise application of vertical load.

Direct Drive Motor

Direct Drive Motor

Direct Drive Motor

A powerful direct drive motor applies precise deformation in the RPA elite. A high quality rheological or dynamic measurement relies on the precise application of a constant rate, step, or periodic deformation. In a direct drive system the start-up delays, compliance, and translational losses seen in clutch or belt driven configurations are eliminated. The superior motor design of the RPA elite ensures that the most accurate and repeatable deformations are always applied to the sample.

The RPA elite applies the highest combination of continuously variable frequency and amplitude in any rubber rheometer. This provides important material information such as:

- The linear viscoelastic response of highly filled rubbers at low strains

- Behavior at extreme processing and use conditions characterized by high strains

- Terminal material behavior exhibited at low frequencies

- Response to high speed deformations measured at high frequencies

Advanced Data Processing

Advanced Data Processing

The complex deformations and stress-strain response common to rubber testing demand the most advanced data processing techniques. The RPA elite from TA Instruments utilizes a state-of-the-art 20 bit encoder and advanced data sampling technique to perform calculations based on a Fast Fourier Transform (FFT) analysis using 90 data points for each cycle of oscillation.

The RPA elite measures and reports non-linearities in torque and displacement. Higher harmonics indicating non-linearity in the applied displacement or measured torque, are reported for each data point, alert the operator with a simple indicator if test conditions are not ideal and storing this information for subsequent data validation.

High Stiffness Torque Transducer

High Stiffness Torque Transducer

The RPA elite benefits from a proprietary wide range ultra-stiff torque transducer. This rugged, non-compliant device measures the widest range of torques accurately and precisely. This greatly improves the accuracy and precision of measured torque, modulus, and viscosity values.

The RPA elite benefits from a proprietary wide range ultra-stiff torque transducer. This rugged, non-compliant device measures the widest range of torques accurately and precisely. This greatly improves the accuracy and precision of measured torque, modulus, and viscosity values.

Dies & Rotors

Dies & Rotors

The MDR one, RPA flex, and RPA elite rotorless shear rheometers employ the industry-standard sealed cavity biconical die design. The dies are constructed from durable, high-stiffness, low thermal expansion stainless steel to minimize system compliance and prevent gap changes with temperature. The test fixtures are connected directly in line with the motor below for precision deformation control and the torque transducer above for accurate measurement.

Direct contact electric heaters mounted within the dies provide exceptional temperature control and stability under isothermal, step and temperature ramp conditions. This highly responsive system returns rapidly to the programmed test temperature upon the addition of a cold sample, providing the most representative values for scorch time and other cure characteristics. Extremely durable user-replaceable seals provide absolute sample containment at all temperatures and conditions.

Die Surfaces

Die Surfaces

The RPA elite die surfaces feature an optimized arrangement of radial serrations to guarantee constant sample contact at even the highest strain values. Polyester or polyamide films may be used to facilitate sample release and avoid the need to clean dies between experiments.

High Pressure Pneumatic System

High Pressure Pneumatic System

The RPA elite employs a high pressure pneumatic system to seal the sample properly and reproducibly. The high capacity pneumatic system applies up to 8 bar nominal pressure to the during gap closure. Proper alignment and the use of mechanical bearings ensure efficient transfer of load from the system to the sample without load frame losses. Actual sealing pressure is measured directly and recorded. This high pressure automated sample containment removes operator dependence and tightly contains the test specimen. This sealing process is particularly important for materials that undergo positive or negative volumetric changes with curing and highly stiff materials such as carbon-filled fluoroelastomers.

The RPA elite employs a high pressure pneumatic system to seal the sample properly and reproducibly. The high capacity pneumatic system applies up to 8 bar nominal pressure to the during gap closure. Proper alignment and the use of mechanical bearings ensure efficient transfer of load from the system to the sample without load frame losses. Actual sealing pressure is measured directly and recorded. This high pressure automated sample containment removes operator dependence and tightly contains the test specimen. This sealing process is particularly important for materials that undergo positive or negative volumetric changes with curing and highly stiff materials such as carbon-filled fluoroelastomers.

Torque Calibration

Torque Calibration

Torque calibration is made simple with a certified torque calibration device. This feature allows the user to calibrate the instrument directly, increasing data confidence and operation time, and reducing the reliance of service engineers for calibration.

Widest range and combination of tests and testing conditions available. Available autosampler for unattended operation.

Rheometer Automation

Rheometer Automation System

Rheometer Automation System

All TA Instruments rotorless curemeters and rheometers are compatible with the highly reliable rubber automation system. This carousel-based autosampler allows for the unattended testing of rubber samples. Coupled with the Scarabaeus Software automated analysis, statistics, and control chart generation, the automated rheometer becomes a highly integrated part of the manufacturing control process.This improved data throughput is also invaluable for screening multiple formulations in a research or product development environment.

Suction Transfer System

Suction Transfer System

Samples are moved from the autosampler tray to the test position using a suction transfer system. This system is highly tolerant of non-ideal sample geometries, so uncured rubber from many sources can be used. Samples are loaded on a carousel and more specimens may be added while another test is in progress, allowing for uninterrupted productivity.

Film Transfer System

Film Transfer System

An automated film transfer system removes the previously tested specimen and advances the film roll to prepare for the next experiment. An integrated sensor alerts the operator at the end of the roll so it can be replaced in a timely manner.

RPA and MDR Experiments

Oscillation and transient tests of curing and viscoelasticity. These tests are the most common for rubber rheology and provide information about vulcanization and curing, viscoelastic properties, filler structure, polymer architecture, and more.

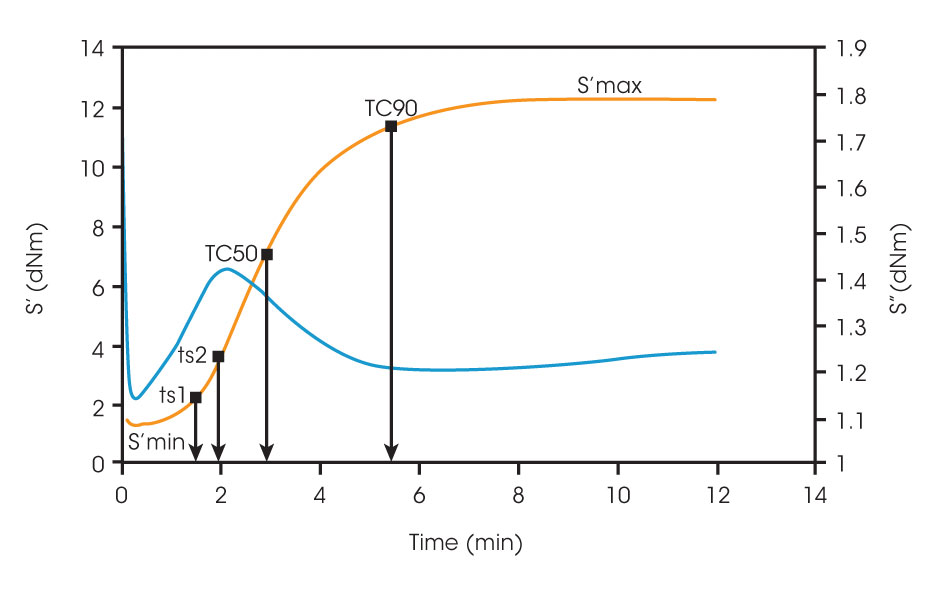

The RPA and MDR instruments perform oscillation, or dynamic measurements of polymer and rubber properties. These tests provide basic torque information, as well as viscoelastic properties such as the storage and loss modulus, tan δ, and viscosity. Oscillation tests are popular for studies of curing, or vulcanization, as well as measurements of viscoelastic properties, filler structure, polymer architecture, and more for both green and cured rubber.

Isothermal Cure

Isothermal Cure

Isothermal cure experiments are critical for rubber and elastomer processing. The TA Instruments rubber rheometers provide high precision data that is simple to analyze. All the important characteristics, such as minimum and maximum viscosity, scorch time, and conversion time can be calculated easily and automatically. The data can also be handled in its complete graphical form for comparison or alternative analyses.

Suitable Instruments: MDR one, RPA flex, RPA elite

Non-isothermal Cure

Non-isothermal Cure

In addition to the industry-standard isothermal cure methods, the RPA and MDR can perform non-isothermal cure experiments. These experiments can be programmed to follow virtually any temperature profile and are especially valuable when simulating manufacturing processes that are not isothermal. Non-isothermal curing experiments may also be coupled with isothermal tests such as strain and frequency sweeps before or after cure to provide a more complete material data set before, through, and after cure.

Suitable Instruments: MDR one, RPA flex, RPA elite

Isothermal Curing at Variable Strain

Isothermal Curing at Variable Strain

While standard test methods often call for a single strain and frequency value to be used for all materials (0.5°, 1.67 Hz), these are not always the ideal conditions for every material. In the present example, the sample material is tested by isothermal cure at three deformation amplitudes, five times each. At the standard of 0.5° and 0.4° the experimental variability is extremely broad. This is because these experiments are performed at strains beyond the linear viscoelastic limit for this material. Testing at a smaller amplitude (0.3°) produces valid data with greatly improved reproducibility.

Suitable Instruments: RPA flex, MDR one, RPA elite

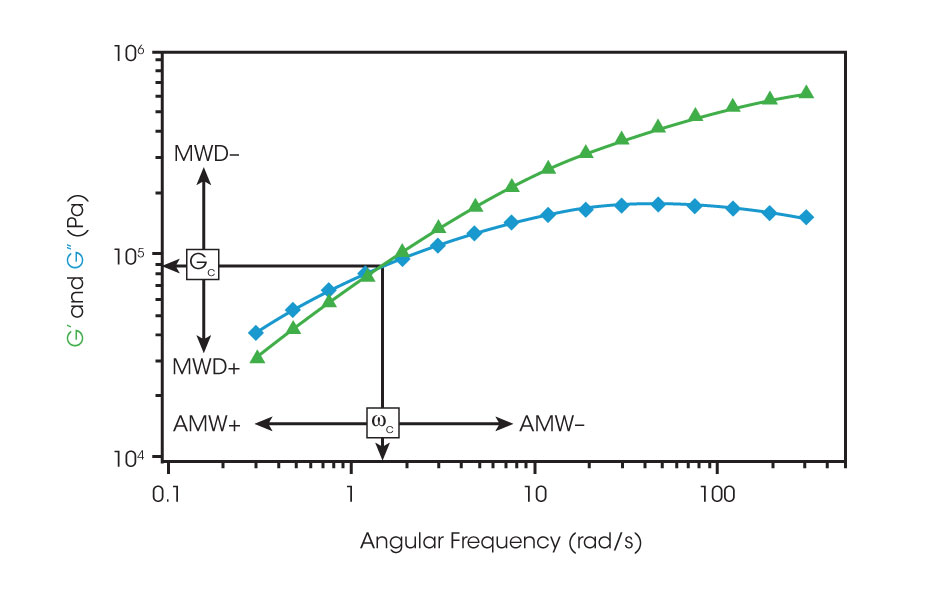

Isothermal Frequency Sweep

Isothermal Frequency Sweep

Measuring the frequency-dependent viscoelastic properties of a material is a powerful way to understand its molecular structure. A frequency sweep as shown can reveal information about the average molecular weight (crossover frequency) and molecular weight distribution (crossover modulus).

Suitable Instruments: RPA flex, RPA elite

Strain Sweep for Filler Loading

Strain Sweep for Filler Loading

The strain-dependent modulus is particularly important as an indicator of the amount and type of rubber filler dispersion and interaction. in the present example, the impact of carbon black addition at five different levels is seen in the low strain region. High strain behavior is generally insensitive to filler addition, as it is less sensitive to filler-filler interaction and more dependent on polymer molecular weight, and polymer-filler interactions.

Suitable Instruments: RPA flex, RPA elite

High Strain Non-Linear Behavior

High Strain Non-Linear Behavior

The viscoelastic response of a material at very high strains differs not only in magnitude from its linear counterpart, but also in type. The careful examination of a polymer’s stress- strain response at high strains reveals features associated with filler content and structure, as well as polymer architecture. in the present example, qualitatively different features are observed at large strains for a linear polymer, branched polymer, and a blend of the two. Both the uncorrelated data, and the FT analysis of periodic data are available through the scarabaeus software to allow in-depth analysis of this new type of data.

Suitable Instruments: RPA flex, RPA elite

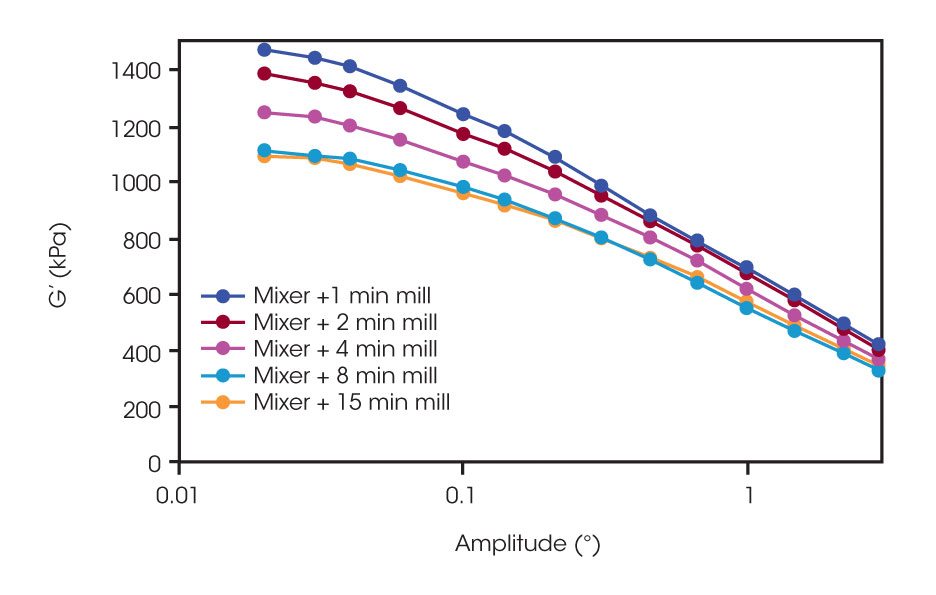

Time Dependent Structure Breakdown

Time Dependent Structure Breakdown

The van der Waals interactions that lead to increased modulus in carbon black filled rubber are highly sensitive to processing. In this example, identical samples are subjected to different lengths of milling after being removed from the mixer. Carbon network structure is reduced with each increase in milling time up to 8 minutes, after which the modulus was unchanged with increased milling. This provides critical information about the amount of milling needed to create a consistent workable material.

Suitable Instruments: RPA flex, RPA elite

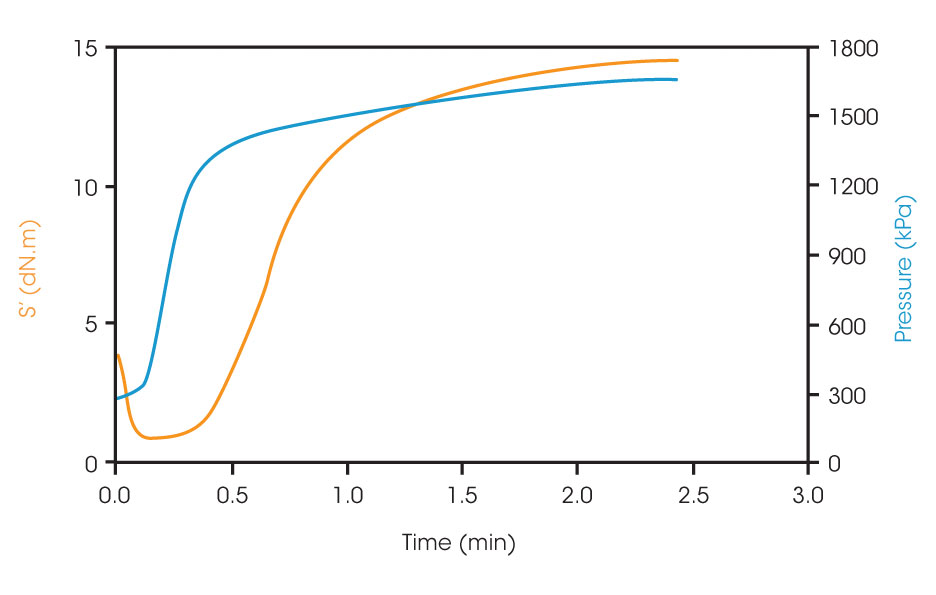

Cure with Blowing Reaction

Cure with Blowing Reaction

Final product density and mechanical performance are often enhanced through the use of blowing agents to create a cellular architecture. These blowing agents generate gas during decomposition in parallel with the curing reaction. Monitoring sample pressure through the curing reaction is an effective way to quantify the blowing reaction, allowing for the characterization of curing and blowing in a single experiment. These two processes must be balanced in order to form the desired cell architecture in the finished product.

Suitable Instruments: MDR one, RPA flex, RPA elite