Scarabaeus Software

Instrument Control and Data Analysis

The Scarabaeus Software for instrument control and data analysis is a powerful and versatile system for programming experiments, providing quick feedback of results, and managing data from all rubber testing instruments. The Scarabaeus Software was developed with customers from the rubber industry and is designed to meet the specific need of production and research.

Designed For Integration

The Scarabaeus Software system for instrument control and analysis integrates and organizes data from multiple instruments and historical tests. Data from RPA, MDR, Mooney Viscometer, Hardness, and Density tests can be organized, compared, and analyzed by material type, inventory order, date, and more. Advanced integration with even greater capability is also available.

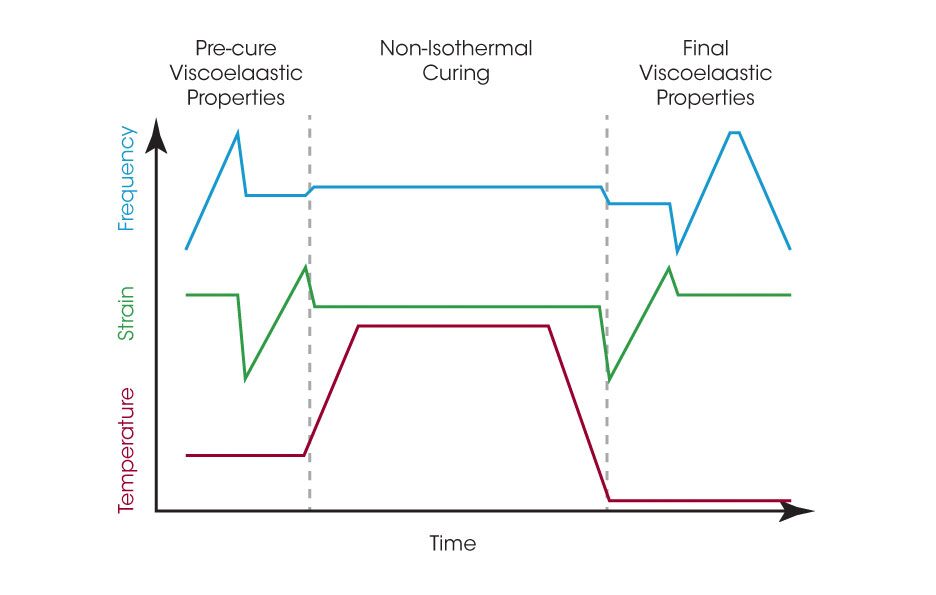

Simple Instrument Control, Flexible Programming

Instrument control software is preloaded with test programs for the most common experiment types, enabling simple operation by new users. Multi-step tests can be easily programmed to collect many types of data from a single specimen, or to mimic an industrial curing or other processing sequence.

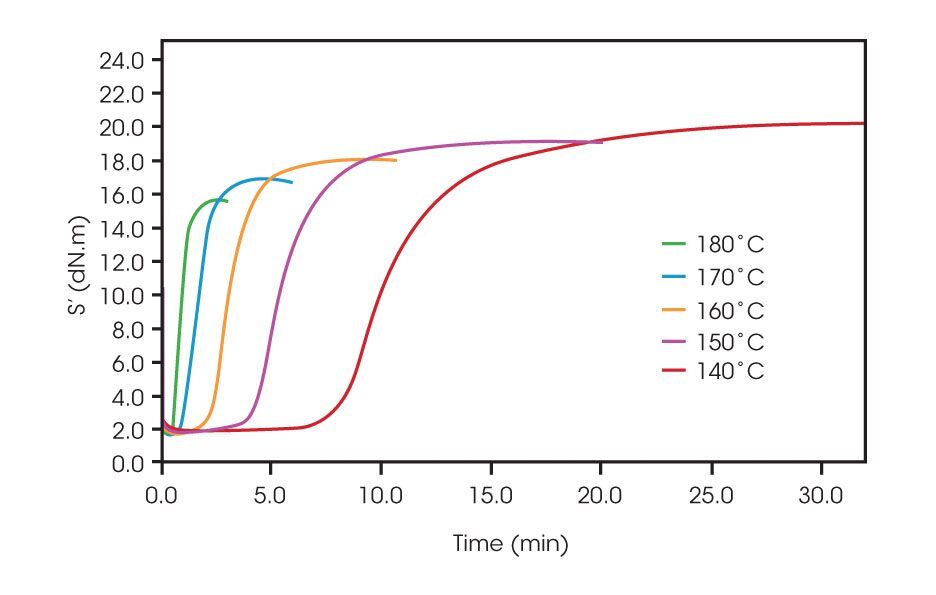

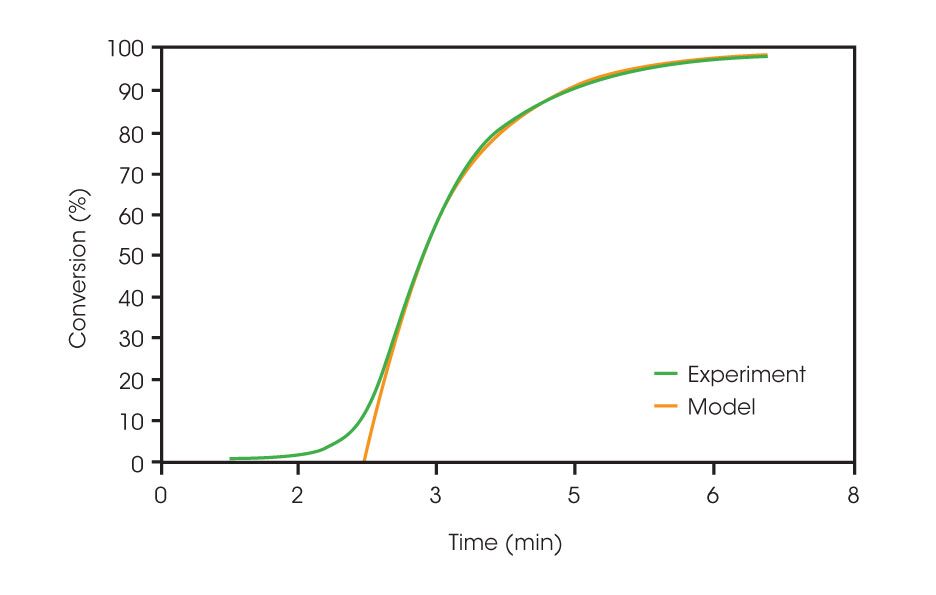

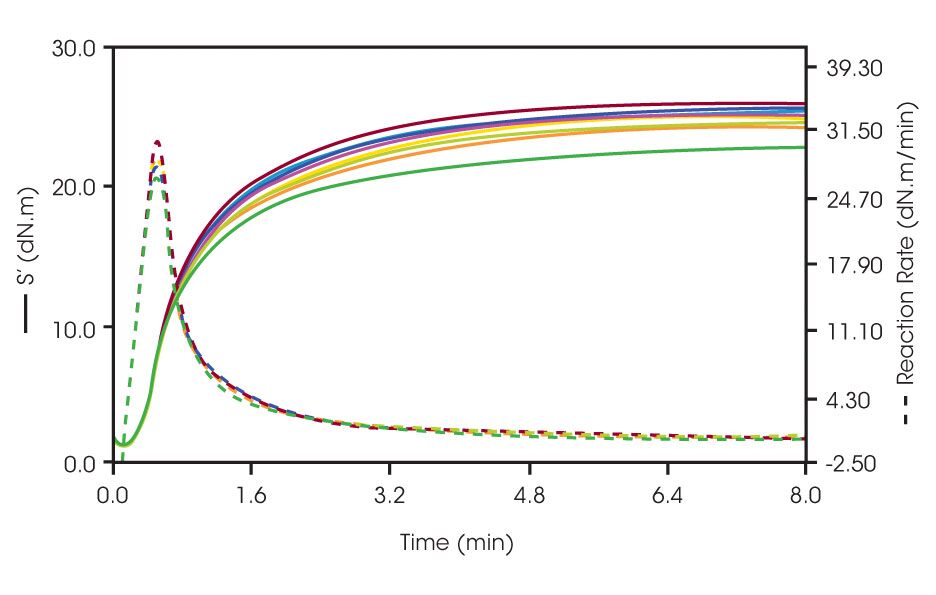

Advanced Data Analysis and Modeling: Curing Kinetics

Isothermal curing data at muliple temperatures can be analyzed according to a rubber-specific methodology to determine curing kinetics parameters. This modeling system can determine:

- Reaction Rate

- Reaction Order, n

- Rate Constant, k

- Incubation Time, †

- Arrhenius Activation Energy, Ea

Statistical Process Control

Test data is readily convrted into actionable information for process control and manufacturing. Automated data analysis can be programmed based on typical performance metrics, such as minimum and maximum torque, scorch times, conversion times, and more. These data are compared against user-defined limits and are used to track processes using histograms, control charts, and summary reports.