The Q400 performs high sensitivity mechanical measurements over a wide temperature range.

View brochure TMA Accessories Contact Us

Sales Promotions

The Q400 is a sixth-generation product from the world leader in thermal analysis. Its performance, ease-of-use, and reliability aptly demonstrate our long experience in designing novel instruments for high sensitivity mechanical measurements over a wide temperature range.

The Q400EM is the industry standard research-grade thermomechanical analyzer (TMA), with unmatched flexibility in operating modes, test probes, fixtures, and available signals. The Q400EM Enhanced Mode allows for dynamic experiments to measure complex, storage and loss moduli, as well as Modulated TMA in which reversing and non-reversing components of displacement are available. It is ideal for research, teaching, and quality control applications, with unmatched performance.

| Temperature Range (max) | -150 to 1,000 °C |

| Temperature Precision | ±1°C |

| Furnace Cool Down Time(air cooling) | <10 min from 600 °C to 50°C |

| Maximum Sample Size – solid | 26 mm (L) x 10 mm (D) |

| Maximum Sample Size – film/fiber Static Operation | 26 mm (L) x 1.0 mm (T) x 4.7 mm (W) |

| Dynamic Operation (Q400 EM only) | 26 mm (1.) x .35 mm (T) x 4.7 mm (W) |

| Measurement Precision | ±0.1% |

| Sensitivity | 15 nm |

| Displacement Resolution | <0.5 nm |

| Dynamic Baseline Drift | <1μm (-100 to 500 °C) |

| Force Range | 0.001 to 2 N |

| Force Resolution | 0.001 N |

| Frequency (Q400 EM only) | 0.01 to 2 Hz |

| Mass Flow Control | Included |

| Atmosphere static or controlled flow | Inert Oxidizing or Reactive Gases |

| Standard | Included |

| Stress/Strain (Q400 EM only) | Included |

| Creep (Q400 EM only) | Included |

| Stress Relaxation (Q400 EM only) | Included |

| Dynamic TMA (DTMA) (Q400 EM only) | Included |

| Modulated TMA MTMAN (Q400 EM only) |

Included |

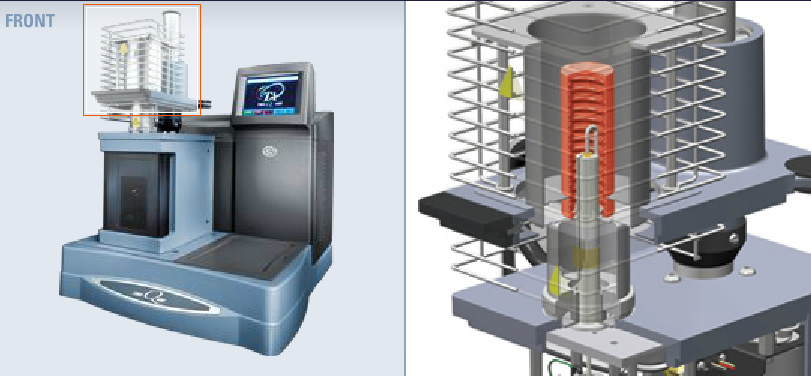

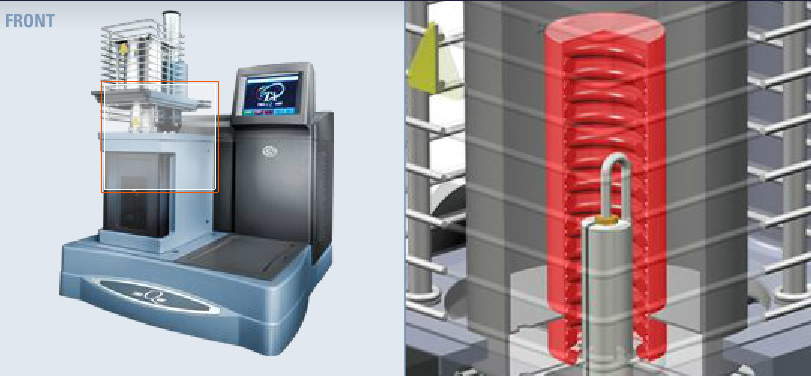

Furnace

FURNACE

- Software-controlled vertical movement

- High performance design for accurate and precise temperature/heating rate control

- Cooling reservoir allows passive (eg. LN2) cooling, or mechanical cooling

- Rugged design ensures long life

Sample Chamber

SAMPLE CHAMBER

- Open architecture for easy sample loading and probe placement

- Purge gas flow is metered by a digital mass flow controller for precise flow rates

- Sample thermocouple is flexible and can be positioned for optimal temperature measurement.

Force Motor

FORCE MOTOR

- Non-contact, friction-free motor for low compliance and the highest force control

- Wide Force Range (0.001 – 2N)

- Software Programmable Force Loading

Transducer

TRANSDUCER

- Movable-core Linear Variable Differential Transducer (LVDT) generates highly accurate output signal directly proportional to dimension change

- Reliable response over wide temperature range

- Positioned below the furnace to eliminate thermal gradient effects

Standard (Q400/Q400EM)

Standard (Q400/Q400EM)

- Constant force, ramp temperature

- Measure coefficient of thermal expansion (CTE)

- Measure deflection temperature under load (DTUL)

- Measure softening point of materials

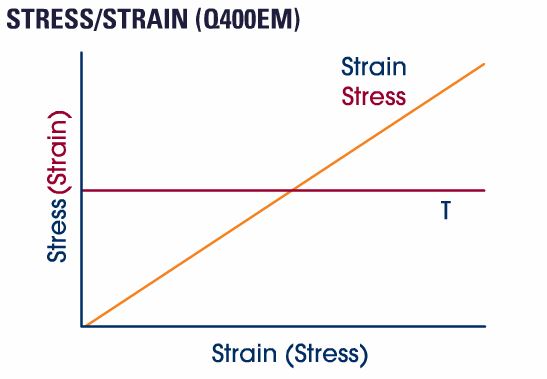

Stress/Strain (Q400EM)

Stress/Strain (Q400EM)

- Ramp stress (or strain), measure resultant strain (or stress)

- Mini-tensile tester mode

- Calculate modulus

- Determine yield stress

Creep & Stress relaxation(Q400EM)

Creep & Stress relaxation(Q400EM)

- Transient testing modes

- Stress (or strain) is held constant over a fixed time

- Determine deformation/recovery properties (creep)

- Determine relaxation modulus vs Time (stress relaxation)

- Excellent tool for predicting material properties

Dynamic TMA Mode (Q400EM)

Dynamic TMA Mode (Q400EM)

- DMA-style test mode

- Sinusoidal forceis applied to the sample

- Resulting strain and sine wave phase difference (d) are measured

- Determine storage modulus (E’), loss modulus (E”) and tan delta as functions of temperature, time or stress.

Modulated TMA Mode (400EM)

Modulated TMA Mode (400EM)

- Sinusoidal temperature modulation is applied to the sample

- Calculate reversing and non-reversing components of dimension change

- Reversing component is useful in detecting subtle glass transitions

- Non-reversing component contains stress relaxations and other kinetic processes

Compression

Compression

Compression

- Sample is measured between two parallel plates

- Sample is subjected to static, linear ramp or dynamic force

- Temperature is either ramped or held constant

- Good, general purpose mode

- Measure compression modulus

Expansion

Expansion

Expansion

- Sample is measured on a flat stage with a flat or hemispherical probe

- Determine coefficient of thermal expansion (CTE)

- Measure glass transition (Tg)

Penetration

Penetration

Penetration

- Uses extended tip probe

- Facilitates higher stress on the sample

- Provides precise measurement of softening temperature Tg and melting

- Provides for measurements of coatings without removal from substrate

3-Point Bending

3-Point Bending

3-Point Bending

- Also known as flexture

- Sample is supported at the ends, deflected in the middle

- Represents fundamentally “pure” deformation as clamping effects are eliminated

- Primarily used with stiff materials, and for temperature distortion measurements

- Special low-friction metallic anvil available for dynamic measurements

Tension

Tension

Tension

- Primarily used for films and fibres

- Measure CTE, Tg, softening temperature, curing, crosslinking, shrinkage force

- Provides for mini-tensile testing

- Dynamic tests can be performed to measure viscoelastic properties (e.g. E’, E”, tan)

5 Year Warranty on Cells and Furnaces

5 Year Warranty on Cells and Furnaces We surveyed 2500 customers and here’s what they said about TA…

We surveyed 2500 customers and here’s what they said about TA… Q400 Thermomechanical Analyzer

Q400 Thermomechanical Analyzer Modulated Thermomechanical Analysis – Measuring Expansion and Contraction Simultaneously

Modulated Thermomechanical Analysis – Measuring Expansion and Contraction Simultaneously New Cyclic TMA Test Protocol for Comparison of Electronic Materials

New Cyclic TMA Test Protocol for Comparison of Electronic Materials Stress/Strain Evaluation of Fibers Using TMA

Stress/Strain Evaluation of Fibers Using TMA Characterization of Polymer Film Penetration by TMA

Characterization of Polymer Film Penetration by TMA Predicting Printed Circuit Board Delamination

Predicting Printed Circuit Board Delamination